Webinar: Supercharge Your Flexible Manufacturing System

OnlineHOW TO TAKE MORE OUT OF YOUR FMS

Learn to Take More Out of Your Flexible Manufacturing

The spindle utilization with Fastems FMS can be over 90% – even in a mixed manufacturing environment with hundreds of different components and new ones constantly introduced. What is the secret? Join our webinar on May 30th at 9 AM CET (Berlin) or 11 AM ET (New York) and learn four key bottlenecks that are preventing you from reaching full potential, as well as strategies to start optimizing your production for higher profits.

Join the webinar and learn:

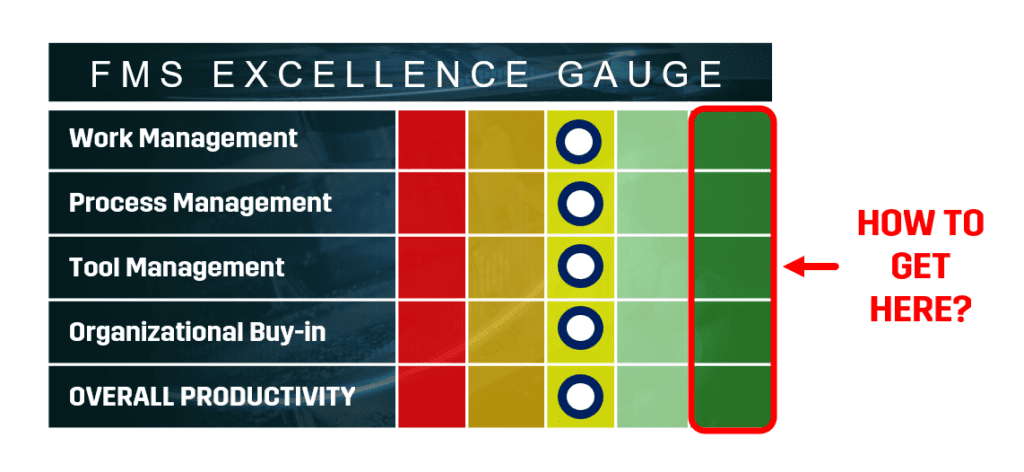

- to evaluate your FMS manufacturing efficiency by using Fastems FMS Excellence Gauge,

- how to manage your work orders and machining setups in FMS-optimal way,

- to build reliable FMS manufacturing environment and processes that can be run with any of your machine tools at any time,

- the best cutting tool management practices with FMS, and

- to engage your whole team with FMS philosophy – how they can benefit of FMS in their daily work

For who is this webinar intended?

- Fastems FMS users – production managers, production engineers, machinists, operators, tool room operators, NC-programmers, and any other role working at least weekly with FMS. Do not hesitate to invite your team members as well!

- Machine tool dealers with customers using Fastems FMS

- Companies considering to take an FMS into use

After the 45-minute presentation, we have a 15-minute Q&A session for the audience to ask questions. The free registration is now open, you are welcome to join!

WHEN

Time and Place

May 30, 2024 at 09:00 CET (Berlin) and at 11 AM ET (New York)

Online webinar (Zoom)

We will send the webinar recording to all the registered people afterwards, so you can register even though you could not join the live session!

PRESENTER

Ilkka Saarimaa, Head of Account Management at Fastems

Ilkka Saarimaa is an experienced Fastems FMS specialist with almost 20 years of CNC automation experience. During these years he has worked with CNC automation services, customer project management, technical sales, account management and product management, concentrating mainly in automating milling machines for mixed manufacturing needs. What is driving Ilkka forward is to see customers taking their full production capacity into use with the help of flexible automation, and turning their machining operations into repeatable processes.